Innovative Printing Technique for Functional Materials with Nano/Microstructures

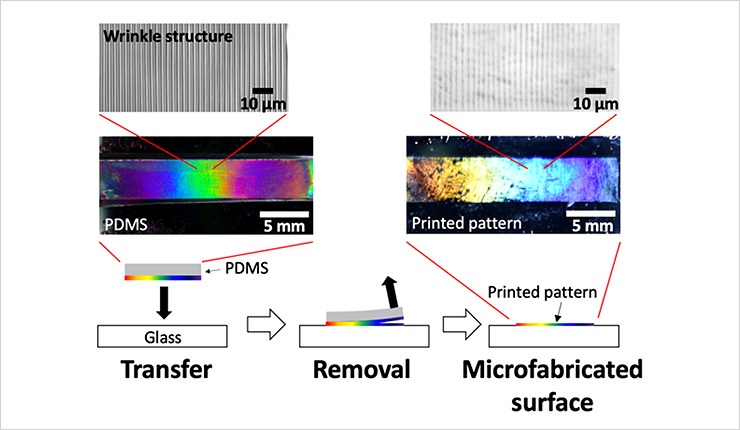

A research collaboration between NIMS and the University of Connecticut has led to a significant advancement in material sciences through the development of an innovative printing technique. This method is designed to fabricate periodic nano/microstructures on the surface of polydimethylsiloxane (PDMS) slabs, which can then be transferred onto glass substrates. **The technique is simple, cost-effective, and does not require large, expensive equipment**, setting it apart from traditional methods. **Periodic nano/microstructures have immense potential due to their unique properties**, like water-repellency, anti-fogging, and the ability to generate structural colors, which are valuable in various applications including innovative gas sensors. **Conventional methods have struggled with scalability and expense**, but this new approach could overcome those barriers by using PDMS as a repeatable and versatile 'ink'. This involves a process where liquid PDMS forms a periodic wrinkled structure on its surface, which can then be transferred effortlessly onto glass. **The team envisions this technology fulfilling social demands for advanced materials**, such as those needed for **atmospheric water harvesting through superhydrophobic and superoleophobic surfaces**. The researchers plan to optimize experimental conditions for different periodic structures to broaden its applicability.