Revolutionary Bioprinting Technique Speeds Up Tissue Fabrication

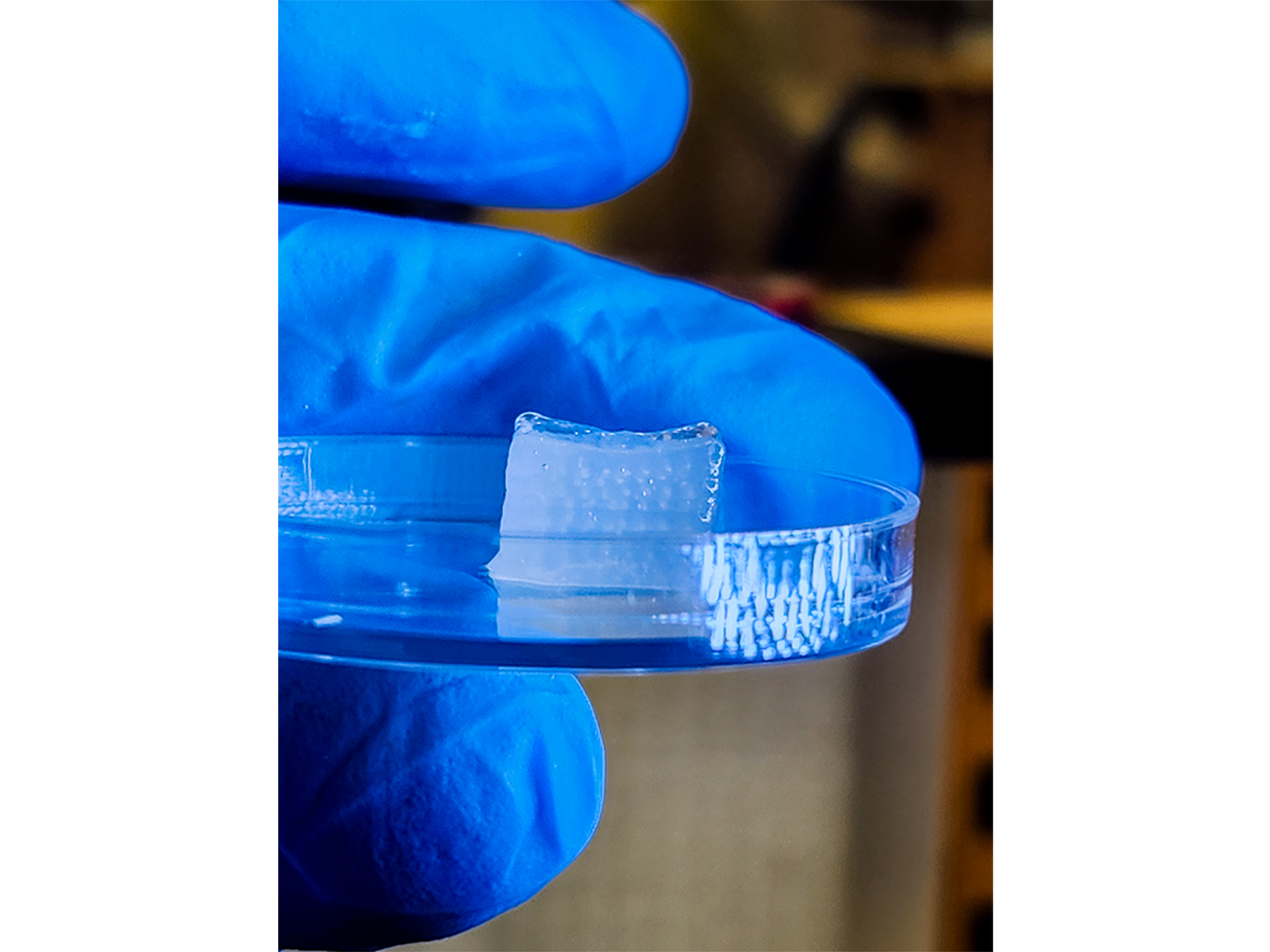

Penn State researchers have unveiled a groundbreaking bioprinting technique using spheroids to create high-density tissues at unprecedented speeds and precision. Unlike traditional methods that struggle with cell density and cause damage during the printing process, this innovative method, known as the High-throughput Integrated Tissue Fabrication System for Bioprinting (HITS-Bio), uses a digitally controlled nozzle array to simultaneously manipulate multiple spheroids. This approach permits **tissue fabrication 10-times faster** than existing technologies while maintaining high cell viability. The team successfully demonstrated its potential in cartilage tissue fabrication, completing a one-cubic centimeter structure in under 40 minutes, significantly eclipsing current capabilities. Remarkably, the technique was applied intraoperatively in a rat model for bone repair, showing accelerated healing. The method promises scalable production of complex tissues with potential applications in **regenerative medicine** and **organ transplantation**. The next step involves integrating blood vessels into tissues, expanding the clinical utility of bioprinted structures. The research received support from the National Institute of Biomedical Imaging and Bioengineering and the National Institute of Dental and Craniofacial Research.